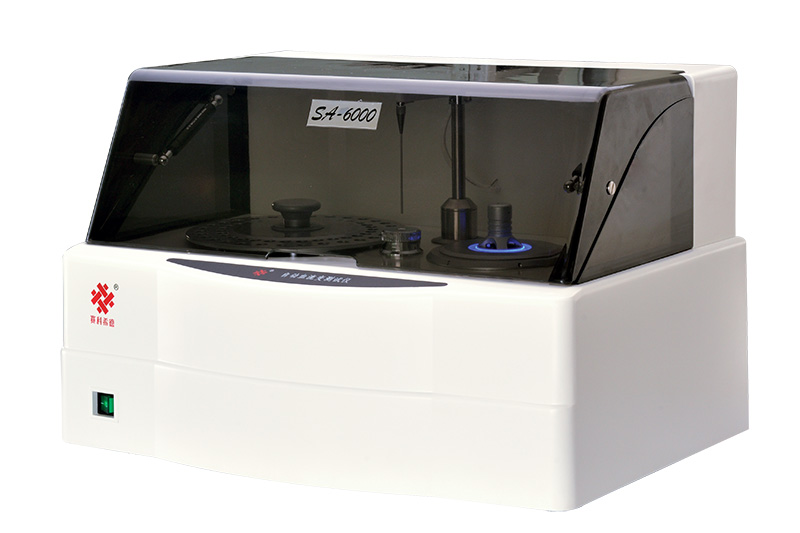

Analyzer Introduction

SA-9000 automated blood rheology analyzer adopts cone/plate type measurement mode. The product imposes a controlled stress on the fluid to be measured through a low inertial torque motor. The drive shaft is maintained in the central position by a low resistance magnetic levitation bearing, which transfers the imposed stress to the fluid to be measured and whose measuring head is cone-plate type. The whole mensuration is automatically controlled by the computer. The shear rate can be set randomly at the range of (1~200) s-1, and can trace two-dimensional curve for shear rate and viscosity in real time. The measuring principle is drawn on the Newton Viscidity Theorem.

Technical Specification

| Test principle |

whole blood test method: cone-plate method; plasma test method: cone-plate method, capillary method; |

| Working mode |

dual needle dual disk, dual methodology dual test system can work in parallel at the same time |

| Signal acquisition method |

Cone plate signal acquisition method adopts high-precision grating subdivision technology; Capillary signal acquisition method adopts self-tracking liquid level differential acquisition technology; |

| Movement material |

titanium alloy |

| Test time |

whole blood test time ≤30 seconds/sample, plasma test time ≤1 second/sample; |

| Viscosity measurement range |

(0~55) mPa.s |

| Shear stress range |

(0~10000) mPa |

| Range of shear rate |

(1~200) s-1 |

| Sample amount |

whole blood ≤800ul, plasma ≤200ul |

| Sample position |

double 80 holes or more, fully open, interchangeable, suitable for any test tube |

| Instrument control |

use workstation control method to realize instrument control function, RS-232, 485, USB interface optional |

| Quality control |

It has the non-Newtonian fluid quality control materials registered by the National Food and Drug Administration, which can be applied to the non-Newtonian fluid quality control of the bid products, and can be traced to the national non-Newtonian fluid standards. |

| Scaling function |

the non-Newtonian fluid viscosity standard material produced by the bidding product manufacturer has obtained the national standard material certificate |

| Report form |

open, customizable report form, and can be modified on site |

Advantages

1. The precision and accuracy of the system meet the requirements of CAP and ISO13485, and it is the preferred blood rheology model for tertiary hospitals;

2. Have supporting standard products, quality control products and consumables to ensure the traceability of the system;

3. Carry out full-scale, point-by-point, steady-state testing, dual methodology, dual system parallel

Maintenance procedures

1. Cleaning

1.1 Correctly connect the cleaning liquid bucket and waste liquid bucket according to the identification of each pipe connector on the rear of the instrument;

1.2 If it is suspected that there are blood clots in the flushing pipeline or the tested specimen, you can repeatedly click the "Maintenance" button to perform maintenance operations;

1.3 After the test every day, use the cleaning solution to rinse the sample needle and the liquid pool twice, but the user must not add other corrosive substances into the liquid pool!

1.4 Every weekend, use cleaning fluid to rinse the injection needle and liquid pool 5 times;

1.5 It is strictly forbidden to use solutions other than those specified by our company! Do not use acidic or chemically corrosive liquids such as acetone, absolute ethanol, or solvent-based liquids for washing and disinfection to avoid damage to the surface coating of the liquid pool and the blood cutting board.

2. Maintenance:

2.1 During normal operation, the user should pay attention to keeping the operating surface clean, and do not allow debris and liquids to enter the inside of the instrument, which will cause damage to the instrument;

2.2 In order to keep the appearance of the instrument clean, the dirt on the surface of the instrument should be wiped off at any time. Please use a neutral cleaning solution to wipe it off. Do not use any solvent-based cleaning solution;

2.3 The blood cutting board and the drive shaft are very sensitive parts. During the test operation and cleaning operation, special care should be taken not to apply gravity to these parts to ensure the test accuracy.

3. Capillary maintenance:

3.1 Daily maintenance

Perform capillary maintenance operations before and after the specimens are measured on the same day. Click the "" button in the software, and the instrument will automatically maintain the capillary.

3.2 Weekly maintenance

3.2.1 Powerful maintenance of capillary tube

Click the "Strong Maintenance" option in the "" drop-down triangle in the software, and place the capillary maintenance solution at hole 1 of the sample carousel, and the instrument will automatically perform strong maintenance operations on the capillary.

3.2.2 Maintenance of the inner wall of the capillary tube

Remove the capillary protective cover, first use a wet cotton swab to gently wipe the inner wall of the upper port of the capillary, then use a needle to unblock the inner wall of the capillary until there is no resistance when unblocking, and finally click the "" button in the software, the instrument will automatically clean the capillary, and then fix it protection cap.

3.3 Common troubleshooting

3.3.1 High capillary calibration value

Phenomenon: ①The capillary calibration value exceeds the range of 80-120ms;

②The capillary calibration value on the same day is higher than the last calibration value by more than 10ms.

When the above situation occurs, "Maintenance of the inner wall of the capillary tube" is required. Refer to "Weekly Maintenance" for the method.

3.3.2 Poor drainage of capillary tube and blockage of the inner wall of capillary tube

Phenomenon: ①In the process of testing plasma samples, the software reports "preparation for test pressure overtime" prompt;

②In the process of testing plasma samples, the software reports "no sample added or capillary clogged" prompt.

When the above situation occurs, "maintenance of the inner wall of the capillary tube" is required, and the method refers to "weekly maintenance".

Login/Register

Login/Register

Business card

Business card Chinese WeChat

Chinese WeChat English WeChat

English WeChat